NOTE:

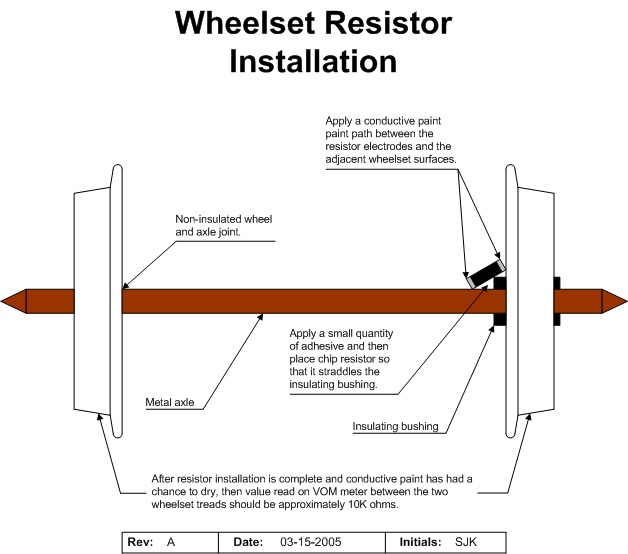

These instructions are for wheelsets with metal axles and

wheels. For wheelsets with metal wheels and non-conductive axles

(e.g.

Kadee) modify these instructions by gluing the resistor to

the center of the axle and using the conductive paint to create

a conductive path from each resistor electrode to a wheel.

Each car should have a minimum of two resistors, one axle per

truck. I install them on the inboard axle, so as to make them

more discrete, but it is up to you. Optimum resistor values are

10,0000 ohms (10K) 1/8 watt or

10,0000 ohms (10K) 1/10th watt. Bear in mind that the 1/8

watt resistors are plenty small, but the 1/10th watt are really,

really small (approximately the size of a Kadee knuckle coupler

spring). Both wattage values will work equally as well.

Resistors cost around 1-2 cents each when purchased in lots of a

1000, but can be even cheaper if they are purchased in

quantities of 5000 or more.

Most chip resistors that have been done to date have been

attached using 5-minute epoxy, which is mixed up in small

amounts to do about 3 or 4 axles at a time. However, an

alternative method being used is

IC-2000 rubberized CA Adhesive (it is the fourth one down on

the page) by BSI (Bob Smith Industries). It is a good adhesive

for attaching resistors to wheelsets since it is a CA type

adhesive so it sets up fast, but not too fast, and it retains

its elasticity (shock resistant) after it dries. Unlike

conventional CA, which can become brittle once it cures.

Rubberized CA is used frequently by the R/C car guys to attach

rubber tires to the hubs, therefore Larry's Hobbies (North

Houston Hobby Dealer) is a good local supplier. A 1 oz. bottle

of IC-2000 runs around $8.00. I understand it is also possible

to purchase BSI IC-2000 at outdoor sporting goods centers, since

it can also be used for patching rubber boots, rafts, etc. The

IC-2000 makes the job go much faster and is ready for the

conductive paint in about 5-minutes after application.

As for the silver print circuit board repair paint, it is

available in a small pen-like applicator and in 1/2 oz. bottles.

The CircuitWorks brand of pen costs about $16, which I've heard

both good and bad things about. I've heard that the pen has a

tendency to clog, but others swear by it, since it can make the

process move along quicker than using a brush. It's up to you as

I've never used it myself. I think the pen can be purchased

locally from Fry's Electronics over on I45 near West Rd. or you

can get it mail order

CircuitWorks Conductive Paint Filled Pen (scroll down to

where it says "CircuitWorks Conductive Paint Filled Pen") I have

no idea which tip size would be better.

The

Silver Print (scroll down to p/n GC-22-023) by GC

Electronics, is available via mail-order for around $25 for 1/2

ounce, which will do thousands of wheelsets. The silver print is

also available in a 1 oz. bottle for those that might want to go

in together to split a larger bottle, since it costs less (about

$42 for 1 oz. bottle). The bottle that the silver print comes in

is actually a liquid nail polish bottle and it has the typical

nail polish type brush attached to the cap. This brush, however,

is way oversized for our needs, so I apply it with a

Floquil

#5/0 red-sable brush. In addition, if you go the route of the

silver print, I recommend you put a few BBs (pre-cleaned in

lacquer thinner, so you don't contaminate the contents with the

light oil that comes on the BBs) in the bottle. The silver print

is made with real silver powder in a lacquer solution and the

pigment is very heavy and likes to settle to the bottom of the

bottle, especially when it sits for long periods of time between

use. In order to get the best results, you really need to shake

it well and BBs help to break up the heavy pigment and make a

nice rattle noise when it is ready for use. Use straight lacquer

thinner to clean brushes.

As for pre-resistored wheelsets, I know of two sources:

Jay-Bee Wheelsets are available through Walthers, and

therefore, available through most hobby shops. However, you most

likely need to special order them. Please note, Jay-Bee

wheelsets have slightly oversized axles to accommodate the

resistors inside the axle. I personally have not used them, but

I have heard some bad things about the quality control on

Jay-Bee Wheelsets on various MRR newsgroups in the past in

regards to the wheelsets not being in gauge or the resistors not

making contact. When you try to regauge them by twisting the

wheelset you end up breaking the continuity between the wheels

and you just end up with a plain old expensive fat-axle

wheelset. They may have gotten a little better with their QA

recently, so its up to you whether or not you want to give them

a try. Walthers lists them for about $2 per axle (sold in

packages of 10).

Another pre-resistored wheelset source is

Logic Rail Technologies

from the Houston, TX area. Logic Rail Technologies supplies

standard NWSL

detectable wheelsets with 15K chip resistors glued on, much

like you would do yourself. 15K is a little on the high-side for

a resistor value, but they will work, just may not be as

reliable as the 10K value. However, with 2 detectable axles per

car, it shouldn't be a problem. Also, if you order a substantial

amount, Logic Rail Technologies may be willing to change the

resistor value to whatever you request. Logic Rail Technologies

price list shows they cost around $9 per 4 axles (approx. $2.25

each).

A misconception of some modelers is that they just plan to

change out one axle per truck and leave the existing axles

installed. Technically, this will work as long as the wheels are

the same diameter, however, the aesthetics of the car can be

compromised. By compromise, I mean HO wheelset profiles are like

snow flakes and differ from manufacturer-to-manufacturer, the

new resistored wheelset profiles will most likely not match the

existing wheelsets leaving the wheels on trucks looking funny

because the wheelset faces will be different. The obvious

solution is to change out all the wheelsets with wheelsets from

the same manufacturer to assure that the wheel-face profiles are

all the same. Since the manufacturers that make resistored

wheelsets also make standard wheelsets, you only have to

purchase one resistored wheelset per truck and then use that

same manufacturer's non-resistored wheelsets for the remaining

axles. The next obvious - and least expensive - solution is to

just add resistors to your existing wheelsets (as long as your

current wheelsets have metal wheels). Adding resistors to your

existing metal wheelsets solves both the unsightly "snow flake"

wheel face profile issue and gives you detectable axles on each

truck for a fraction of the cost.

In closing, you can make your car detectable for mere pennies

per axle, but they are available commercially if you wish to go

out and purchase them pre-made. In addition, you are free to

paint the wheelsets after you apply the resistors and silver

print if you like, however, it is recommended that you mask the

wheelset tread before painting or clean it thoroughly after

painting since the paint will severely inhibit the detectability

of the wheelset.

|